UV( Area illuminant)

model : UV800 (Series)

1.(technical parameter):

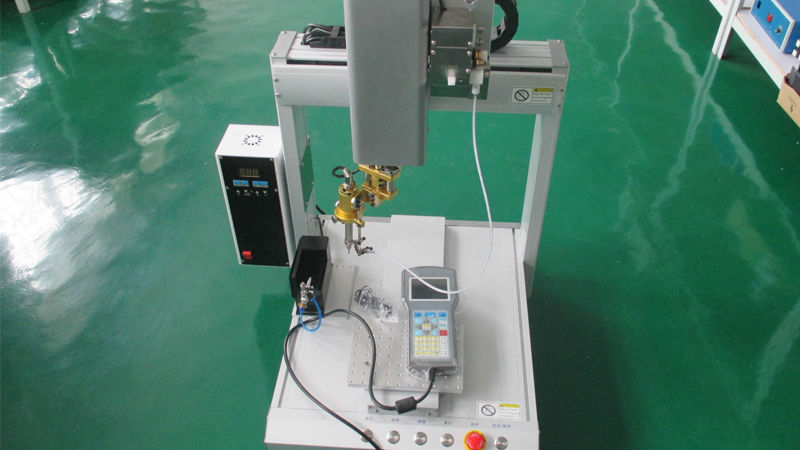

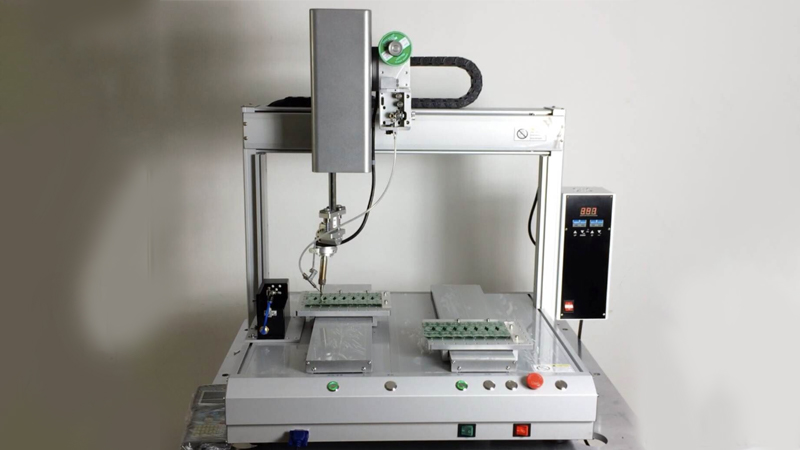

1.Controller size: 400x300x260(LxWxH), light cover size: 300x300x480(LxWxH),unit:mm.

2.UV-LED light source size: 200x100 (mm)

3.UV light, with wavelengths of 365nm, 385nm, 395nm, 405nm (optional)

4.Total power: 350-600 (optional)

5.Heat dissipation mode: air cooling

2.(Product Features):

1.Intelligent UV power supply + product photoelectric detection + UV hood;

2.This product mainly includes controller, UV-LED irradiation head and connection cable, special light cover. The cover to prevent ultraviolet radiation from injuring people, to ensure the safety of the operation.

3.UV-LED irradiation head is integrated with imported high-intensity ultraviolet LED, supports external signal input and trigger, and can be used with semi-automatic or automatic production line;

4.Simple operation and easy to install. Perfect combination with the production line, save labor costs, effectively improve the production efficiency;

5.Photoelectric sensor, photoelectric automatic detection products, when the product reaches,the bottom of the UV light source can automatically illuminate time, the product leaves the UV surface light source area automatically turn off the light standby to save power.

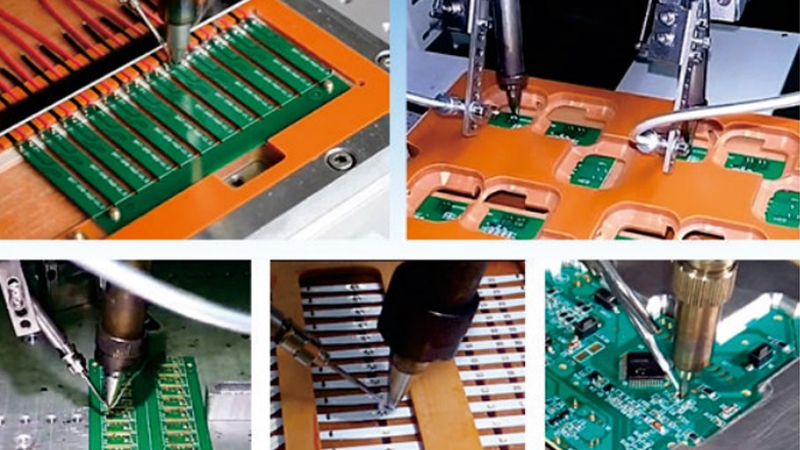

3.(applied range):

The irradiation system of this product adopts imported high strength LED luminescence mode, which can choose 365nm, 385nm, 395nm, 405nm wavelength, different power LED corresponding to curing different UV glue, UV ink, UV light oil, UV paint, etc.

4.(usage method):

Install the equipment on the production line, the UV-LED light source box is placed on the belt transmission line, the irradiation surface faces the belt surface, adjust the position, set the light source brightness and curing time, transfer the product requiring UV curing from the belt through the UV-LED light source, after the irradiation reaches the set time, the product is cured.

Previous: No More

Next: Vacuum inhale equipment